Quality as a Service (QaaS) for automated inspection of textile products

Automating the quality control process in textile industry is one of the trending innovations in that sector, and DigInnoCent presents an innovative system that can bring profits to textile manufacturers by increasing the quality and precision of their products.

Moving towards automated fabric inspection

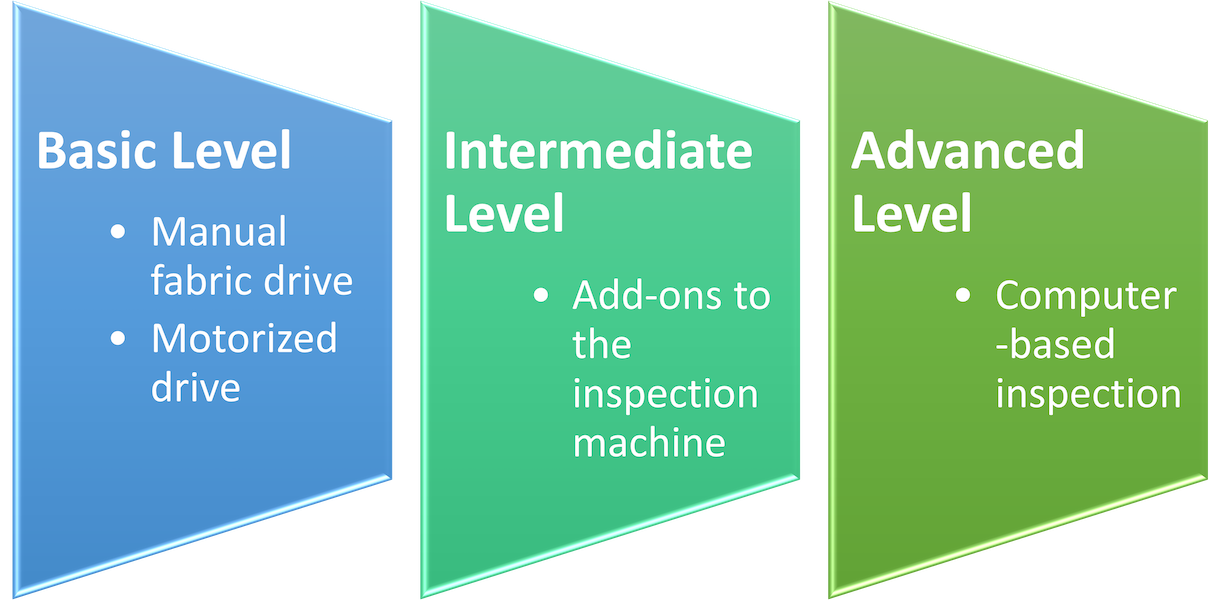

The majority of fabric inspection machines available in today's market rely on the conventional method of visual inspection performed by human operators. However, this approach has several drawbacks, as it is prone to variability in the operator's attention level during the shift, resulting in inconsistent inspection results. Furthermore, it can be financially inefficient, particularly in countries with high labor costs, such as many European nations.

State-of-the-art technologies

DigInnoCent s.r.o. developed innovative state of the art Computer Vision and Artificial Intelligence algorithms. Through our "Quality as a Service" innovative system, we offer our expertise to textile manufactures to inspect their products, where they do not need to buy expensive equipment or hire more workers to perform high quality inspection according to the required Product Standards.

Textile ecosystem is among the most globalized value chains that exist today. Innovations in this sector were, historically, the engine behind industrialization of many countries, and new technologies in this sector always have a great opportunity to succeed and grow. Automating the quality control process of textile is one of the trending innovations in this sector, and DIC presents an innovative system that can bring profits to textile manufacturers by increasing the quality and precision of their products.

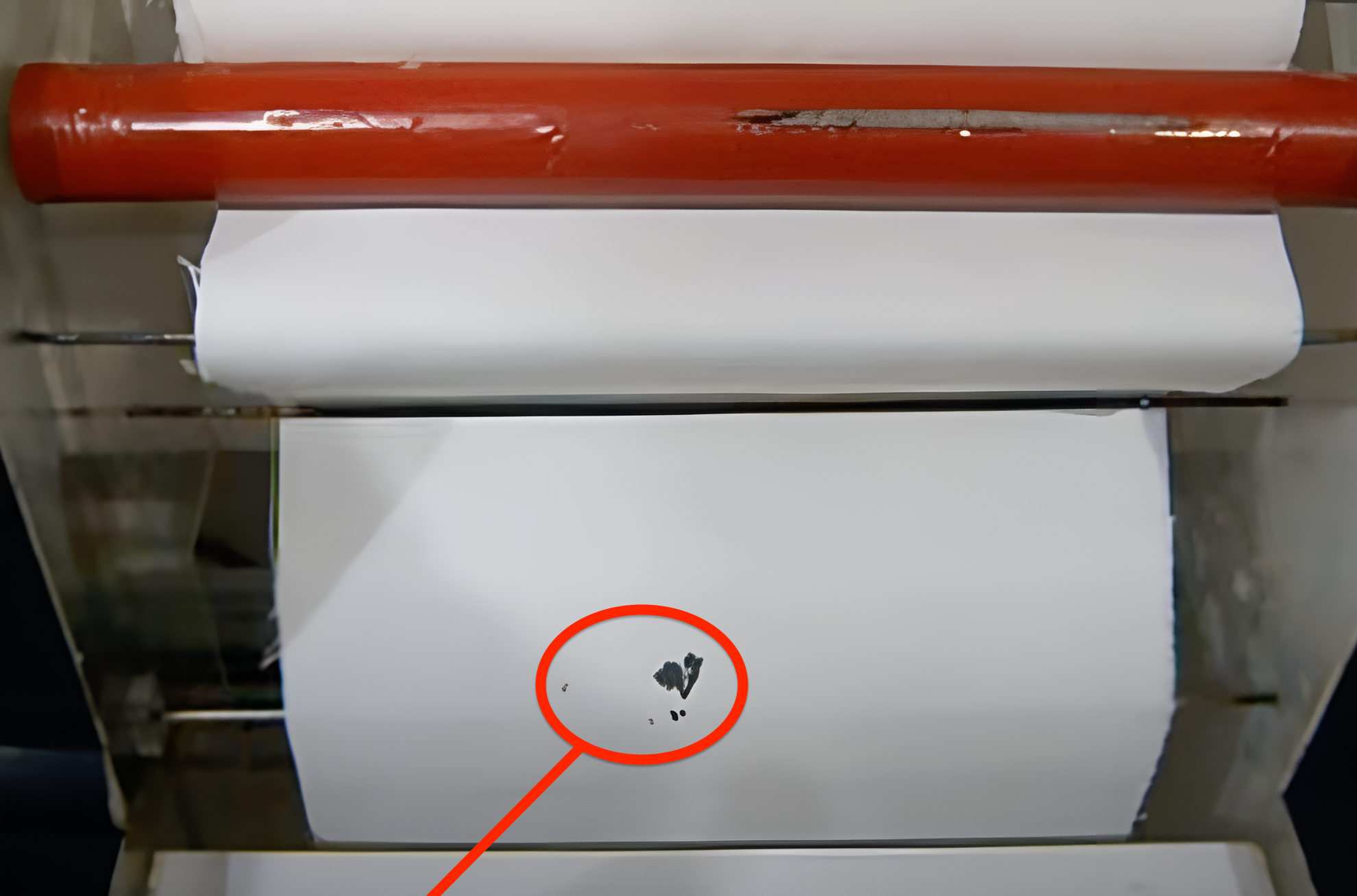

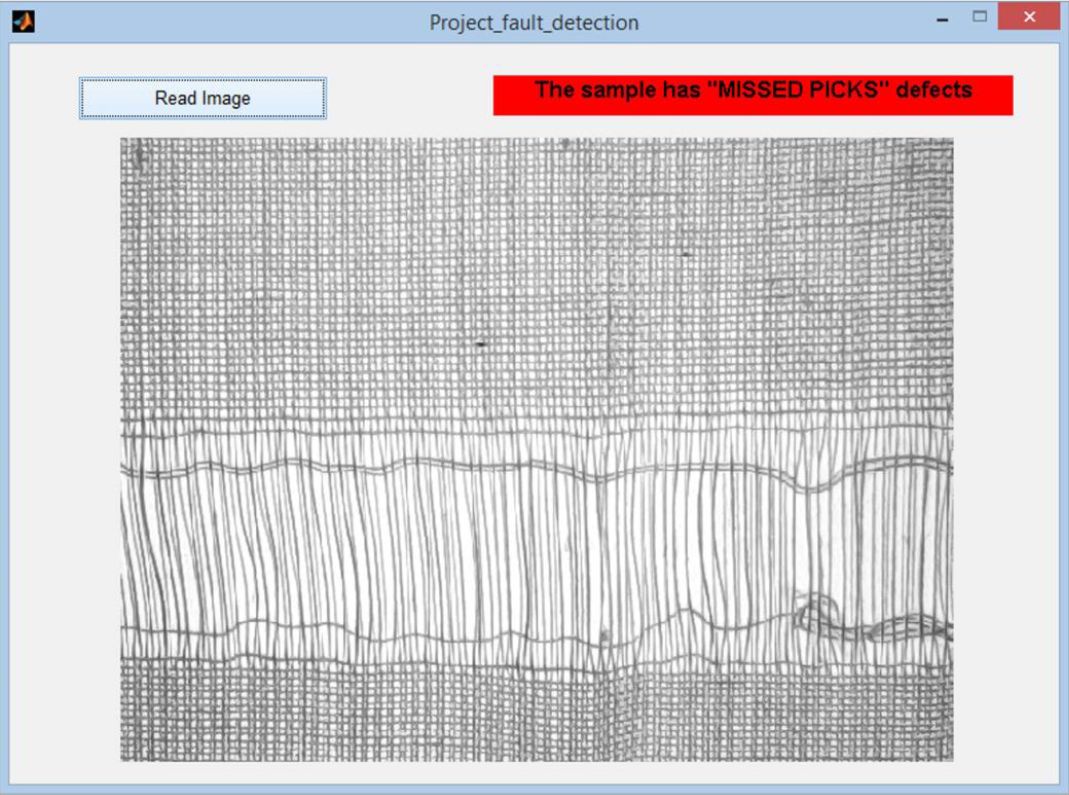

Accuracy, speed, and reliability in detecting, classifying, and grading the fabric defects

Our system has high compatibility, flexibility, and adaptability to different types of fabrics, fabrics conditions, and inspection standards. We promise the textile manufacturers with cost-effectiveness, efficiency, and productivity in the inspection process.

Increasing demand, awareness, and quality standards in the textile industry

DIC offers optical inspection systems that use cameras and sensors to capture images or data about the fabric, and to identify defects, such as holes, stains, color variations, or texture abnormalities. The system uses a combination of hardware, software, and algorithms to analyze the fabric, and to compare the fabric against a set of quality standards or specifications.

We offer advanced automation technologies, based on computer vision, artificial intelligence, internet of things, etc.

Computer vision (CV)

CV is the field of computer science that focuses on the development of algorithms, libraries, and tools for the analysis and interpretation of images and video. Computer vision technologies are used in our product to automatically capture, process, and analyze the images of the fabric, and to identify the defects or characteristics of the fabric.

Artificial intelligence (AI)

AI aims to simulate the cognitive or decision-making abilities of humans. AI technologies are used in our QaaS system to automatically learn, adapt, and improve the performance of the system, and to provide intelligent, real-time, or predictive analysis of the fabric and its defects.